Automotive Cover Glass

Development and Mass Production of 3D Curved Large Tempered Glass

for Automotives

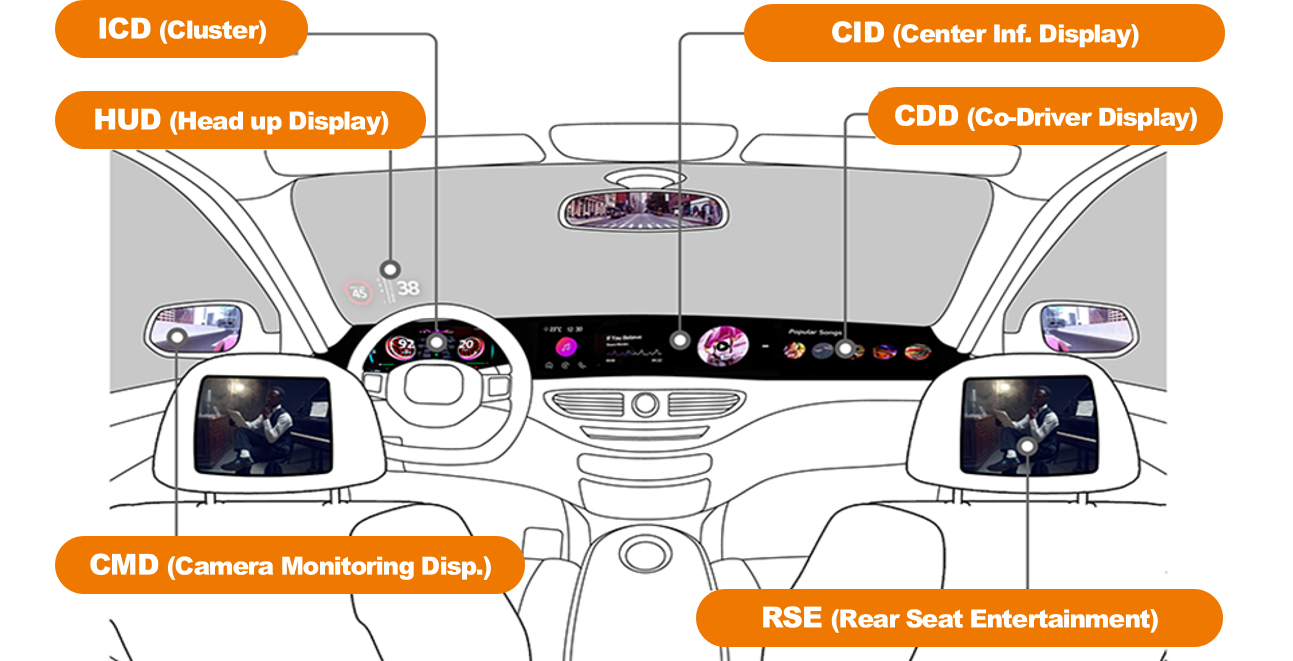

As the automotive trend has shifted to automated driving and connected vehicles (SDVs), automotives are now expanding beyond by means of transportation but to a part of the living space. Converged with electronics and information and communication, the automotive electronics business is rapidly changing into a core field of technology competition that encompasses all sectors, including design, materials, and parts. It's developing into a variety of products such as a digital cluster, a Center Information Display (CID), and a Co-Driver Display that provide a variety of information and entertainment to drivers and passengers, and is evolving into large, slide, curved, and full size shapes.

JNTC is leads the automotive electronics market by developing and mass-producing 3D curved tempered glasses of full size screen for automotives, and is developing products of various shapes through in-house AG/AR/AF Coating, 3D molding and printing processes, which are key technologies for product differentiation.

Based on this, JNTC will develop a variety of curved, bended shapes, and P2P (Pillar To Pillar) super-sized tempered glasses to take an exclusive position in the field of automotive display business.

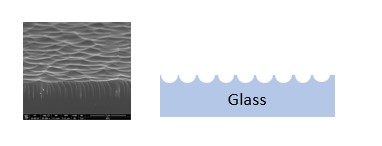

Core technology

| Process | Etching AG | Spray AG | Glass Forming |

|---|---|---|---|

| Concept |

|

|

|

| Technology |

- Reduce the glare phenomenon by improving the diffuse reflection of light - T-haze 2~8% - 1,460 X 380mm 2D flat surface - Used on high resolution display |

- Reduce the glare phenomenon by improving the diffuse reflection of light - Used for various shapes (2D,3D) - Relatively easy for visual defects improvement because coating process comes after shape forming - High productivity by utilizing conveyor process - Low maintenance cost |

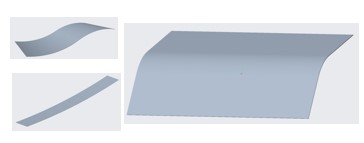

- Relatively high design flexibility due to its forming process(Hot forming) - Capable of asymmetric curved surface |

| Process | Screen Print | Spray Print | E-beam Coating |

| Concept |

|

|

|

| Technology |

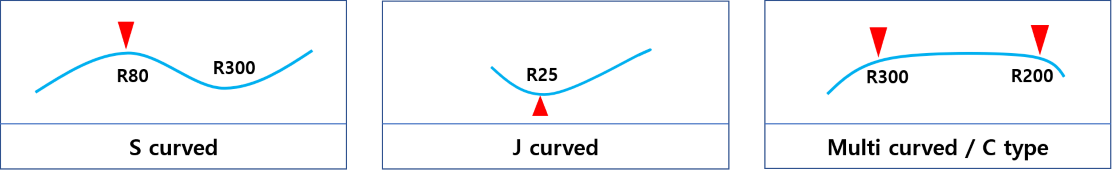

- Silk printing on the curved surface - Vision align method - Printing on flat / curved surface - Round type, J type |

- 1 layer printing (Minimum printing thickness : 5㎛) - Possible to print on unstructured glass - Multi, J-type, S-type, double curvature, etc. |

- 2D, 3D product AR/AF coating - Distance between source and product is far,which enables to accommodate large 3D glass - 3~6 layer structure - Surface hardness after AF coating : 9H (With AG, 3H) |

Specification

| Outer Size | Maximum 1500 x 400mm (Pillar to Pillar) | ||

|---|---|---|---|

| Glass | Type | AGC, Corning, NEG, Panda etc. | |

| Thickness | 1.1t, 1.3t, 2.0t | ||

| Shape | 2D | Design implementable | |

| 3D | 3D Rounding (R) | Customized for customers - Min. R25 | |

| Height (H) | Customized for customers | ||

| Surface | Direct | AG/AR/AF (AG : Etching & Spray) | |

| ASF | Dexerial, Nitto, etc. | ||

| Purpose | ICD, CID, CDD, DID, RSE, etc. | ||

| Others | AR Hard coating | ||