R&D Results

Secure new technology and strengthen technological competitiveness

through

continuous R&D investment

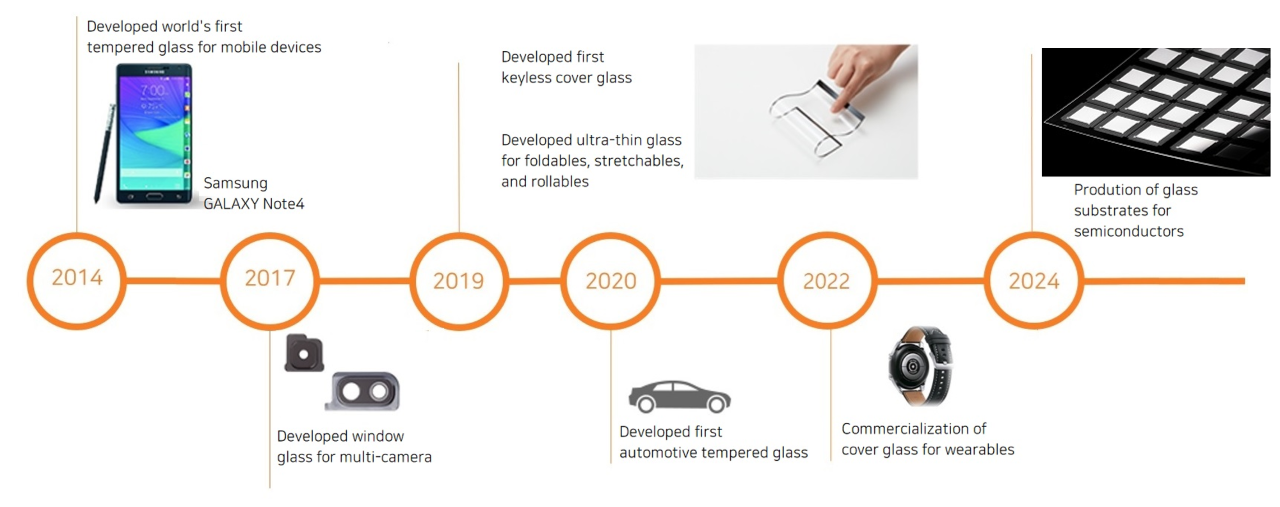

JNTC succeeded in mass production of 3D cover glass for the first time in the world in 2014, and heralded the advent

of edge smartphones to the world by exclusively supplying it to Samsung Electronics' first edge phone, Note 4. After

that, the application of 3D cover glass to the worldwide edge phone design trend began in earnest, and a

double-sided edge, large area bezel-less 3D design smartphone was released. Based on this, JNTC has been changing

the paradigm of the smartphone market by providing differentiated value to customers around the world.

Following the commercialization of 5G in 2019, the world's first keyless 3D cover glass without left and right

button keys of existing smartphones has been developed and supplied exclusively, and we have secured leading

technology for ultra-thin glass for foldables, stretchables, and rollables based on advanced technology of

high-performance, high-spec thin-film glass. In 2020, we are planning to enter the global market by developing and

commercializing the world's first integrated 3D cover glass for automobiles.

As the global smartphone market trend demands high-capacity high-speed signal transmission and waterproofing, the

connector market is also growing. JNTC developed high-functional connectors such as 5G, C-TYPE, and waterproof in

2016 and has expanded the scope of supply to 5G phones.

In addition, we mass-produced camera windows for

smartphones in 2017, and since 2018 we have expanded the scope to multi cameras in line with the improvement of the

camera function for smartphones.

We have been launching global No.1 products.

R&D Projects

| Year | R&D Project | R&D Result | Application |

|---|---|---|---|

| 2023 |

Hearts watch backcover |

|

SAMSUNG (Galaxy Watch 5) Application of backcover glass |

| 2023 |

HD109 Project |

|

HONOR (HONOR 100) Application of cover glass |

| 2023 |

DP389 Project |

|

Huawei (NOVA 12 PRO) Application of cover glass |

| 2023 |

DP362 Project |

|

Huawei (MATE 60 PRO) Application of cover glass |

| 2022 |

S23 DM1 |

|

SAMSUNG (Galaxy S23) Application of cover glass |

| 2022 |

S22 R0 |

|

SAMSUNG (Galaxy S22) Application of cover glass |

| 2021 |

Watch(fresh) |

|

SAMSUNG (Galaxy Watch 4) Application of cover glass |

| 2021 |

DP213 |

|

Huawei (P50 PRO) Application of 3D Cover glass |

| 2020 |

DP173 Project |

|

New 3D cover glass |

| 2019 |

DP150 Project |

|

Huawei (P40Pro) cover glass |

| 2019 |

DP116 Project |

|

Huawei (mate 30 Pro) cover glass |

| 2018 |

Storm Project |

|

LG (V40) cover glass |

| 2018 |

DP076 Project |

|

Huawei (MATE 20 PRO) cover glass |

| 2017 |

Automotive 3D integrated CG Project |

|

Cluster + CID integrated 3D cover glass |

| 2017 |

Taimen Project |

|

cover glass |

| 2017 |

S-Con Project |

|

Audi Automotive cover glass prototype |

| 2016 |

G8918A Project |

|

Chinese-type Mobile cover glass mass-production |

| 2016 |

Noble CAM Project |

|

Galaxy Note camera window mass-production |

| Year | R&D Project | R&D Result | Application |

|---|---|---|---|

| 2024 |

USB 3.2 Type-C MIM Type |

|

|

| 2023 |

USB 3.2 Type-C MIM Type |

|

|

| 2023 |

USB 3.2 Type C MIM Type |

|

|

| 2021 |

USB 2.0 Type C DeepDrawing Waterproof |

|

|

| 2020 |

USB 3.2 Type C DeepDrawing Waterproof |

|

|

| 2018 |

USB Type C 3.1 internal/external |

|

|

| 2018 |

Waterproof EAR JACK (FPCB all-in-one) |

|

G7 & CV Series |

| 2017 |

Nano SIM Socket |

|

Galaxy A Series |

| 2017 |

Camera Socket |

|

Galaxy J Series |

| 2016 |

Micro USB 5P Plug |

|

Charger, DLC |

| 2016 |

USB Type C 3.1 Internal waterproof Socket |

|

Galaxy S, Note |

| 2016 |

USB Type B Waterproof Socket |

|

Galaxy S |

| Year | R&D Project | R&D Result | Application |

|---|---|---|---|

| 2024 |

TGV1 TGV1 |

|

|